How To Negotiate With Fitness Wear Manufacturers For The Best Deal?

2024-02-01

2024-02-01

Sansansun

Sansansun

Introduction

Navigating negotiations with Fitness Wear Manufacturers demands are astuteness in dialogue and strategic acumen. Initiating dialogues, our aim hinges on fabric durability, stitch resilience, and moisture-wicking technology. Acronyms like GSM (Grams per Square Meter) and RPM (Revolutions per Minute) dominate these conversations.

Mastering terms such as flatlock seams and compression fit enhances bargaining power. Optimizing attire performance, we delve into technical specifications, fabric blends, and ergonomic designs. Grasping these elements, our negotiation journey with Fitness Wear Manufacturers commences, aiming for advantageous outcomes.

Understanding the Fitness Wear Manufacturing Landscape!

·What are the types of fitness wear manufacturers?

§OEM Suppliers

In the realm of fitness wear, Original Equipment Manufacturers (OEM) play a pivotal role. They fabricate garments based on exact specs, ensuring precise measurements for athletic wear. These entities blend diverse fabric types, creating unique blends.

Their expertise encompasses a broad range of fitness apparel, tailoring to specific athletic needs. OEMs incorporate cutting-edge fabric tech, enhancing performance wear. Their production spans vast SKUs, catering to varied fitness regimes.

Their process involves intricate steps, from design to final stitching. These suppliers are integral to the sportswear sector, providing bulk quantities. Their role in the market is characterized by large-scale operations.

§ODM Factories

Original Design Manufacturers (ODM) in fitness wear stands out for their design-centric approach. They offer comprehensive solutions, from concept to completion. ODMs specialize in crafting exclusive fitness apparel lines. Their forte lies in creating trendsetting designs.

They employ innovative tech in fabric development. ODMs navigate complex design processes seamlessly. Their production facilities are equipped with advanced machinery. Their market presence is marked by unique style offerings. ODMs cater to brands seeking distinct design identities.

§Private Label

Private label manufacturer carve a niche in the fitness industry. They offer tailored branding solutions for fitness apparel. Their services encompass logo customization.

These manufacturers are known for their bespoke product lines. They cater to brands seeking to establish a unique presence. Their operations are aligned with client branding strategies. Private label producers are crucial for brand differentiation. They facilitate brand-specific product launches. Their role is pivotal in creating brand-exclusive lines.

§Contract Manufacturers

Contract manufacturers in fitness wear are known for their flexible production capabilities. They operate on a contractual basis, offering adaptable manufacturing solutions. Their services are ideal for seasonal or limited-edition lines. They excel in handling variable production volumes.

Their agility in production adapts to market demands. They are key players in time-sensitive product rollouts. Their operational model is based on client-specific contracts. They are instrumental in managing fluctuating market needs.

§Vertical Integrators

Vertical integrators in fitness wear manufacturing embody end-to-end control. They oversee the entire production cycle, from raw material to finished product. Their integrated approach ensures consistent quality. They manage all aspects of manufacturing, streamlining processes.

Their business model is characterized by in-house operation control. Vertical integrators are pivotal for maintaining supply chain efficiency. They offer a consolidated solution for fitness wear production.

§Niche Producers

Niche producers in fitness wear focus on specialized segments. They cater to specific athletic disciplines with targeted apparel. Their production is centered on particular sportswear categories. They excel in creating highly specialized fitness garments.

Their market presence is defined by focused expertise. Niche producers are key to catering to specialized fitness needs. They offer products designed for specific athletic activities. Their role is crucial in meeting the demands of niche markets.

·Geographic considerations: Local vs. international manufacturers

§Local Sourcing

Local fitness wear creators bolster regional economies. They offer rapid turnaround times, fostering agility in production. Proximity to these manufacturers aids in real-time collaboration.

These entities often have an intricate understanding of local market trends. Working with them minimizes logistical hurdles, enhancing delivery efficiency. Local sourcing allows for hands-on quality control. It fosters strong community ties and supports local business ecosystems.

These manufacturers usually adhere to regional regulatory standards. Close proximity to these sources facilitates easier scalability adjustments. Local sourcing often results in reduced carbon footprints.

§Overseas Production

International production in fitness wear opens a global talent pool. It often offers cost advantages due to varied economic scales. Overseas manufacturers might have access to unique materials and techniques. They provide opportunities for tapping into international market trends.

However, this can introduce complexities in communication due to time zone differences. Overseas production can offer diverse design perspectives. It may lead to exposure to new manufacturing technologies. However, it involves navigating through complex international trade regulations. There's a reliance on international logistics, which can be more intricate.

§Export Incentives

Export incentives significantly influence global fitness wear production. They often lead to competitive pricing due to governmental subsidies. These incentives can open up new markets for manufacturers.

They may encourage higher standards in production quality. Export incentives can lead to increased production capacity. They often result in enhanced global brand visibility.

Such incentives can catalyze technological advancements in manufacturing. They might lead to beneficial trade agreements. Export incentives could result in a broader range of products available globally. However, they may introduce competition in domestic markets.

§Tariff Impacts

Tariffs heavily sway the international trade of fitness wear. They can lead to increased product costs, affecting consumer price. Tariffs might encourage local production over imports.

They can result in shifts in global manufacturing hubs. Tariffs may lead to strategic partnerships to circumvent trade barriers. They could result in diversification of supply chains.

Tariffs might influence material sourcing decisions. They can impact the overall competitiveness of products in international markets. Tariff changes can lead to abrupt adjustments in business strategies.

§Logistics Complexity

Logistics in global fitness wear manufacturing present multifaceted challenges. It involves coordinating across diverse transportation networks. Logistics complexity can lead to variability in delivery timelines.

It requires adept handling of customs and import/export regulations. Global logistics demands robust planning to manage supply chain disruptions. It involves balancing cost-efficiency with timely deliveries.

Logistics complexity can necessitate advanced technology for tracking and management. It requires strong global partnerships for smooth operations. Navigating logistics is pivotal for maintaining inventory balance.

§Cultural Differences

Cultural nuances significantly impact fitness wear manufacturing. Understanding local cultural preferences is key for product relevance. Cultural differences influence design aesthetics and functionality. They necessitate tailored marketing strategies for different regions.

Acknowledging cultural norms can enhance brand appeal. Adapting to cultural variations requires flexible production approaches. It involves sensitivity to local customs and traditions.

Cultural understanding can lead to innovative product designs. It's crucial for building global brand recognition and trust. Cultural adaptability can become a unique selling proposition.

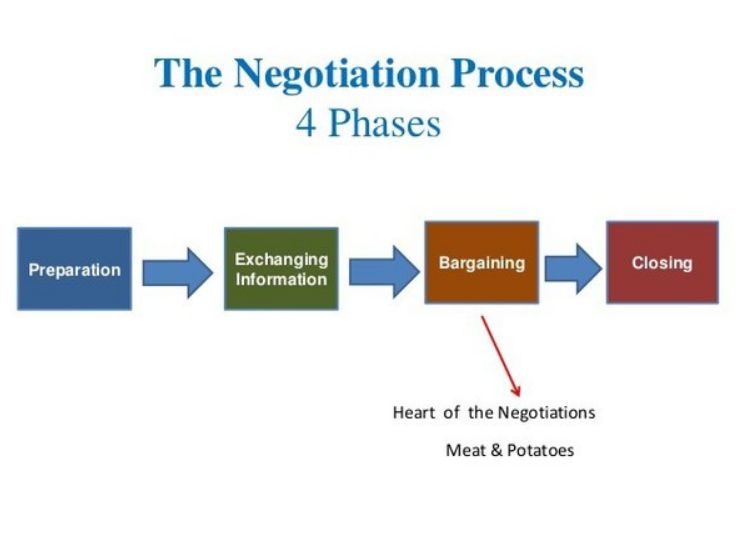

How To Prepare For Negotiation? Essential Steps?

·Market Analysis

Analyze market dynamics to understand fitness wear trends. Study consumer behavior patterns specific to athletic apparel. Evaluate competitor strategies in the fitness wear domain.

Assess market share and positioning of key fitness wear brands. Identify emerging trends in fitness wear styles and materials. Analyze pricing strategies within the fitness wear market.

·Demand Forecasting

Predict upcoming trends in fitness apparel demand. Use historical sales data for demand projection in fitness wear. Incorporate seasonal variations in forecasting fitness wear sales.

Analyze fitness industry growth trends for demand estimation. Health and wellness trends influencing fitness wear demand. Utilize advanced analytics for accurate demand forecasting.

Forecast demand based on fitness activity popularity. Align product development with forecasted demand patterns.

·Budget Allocation

Allocate funds towards key areas in fitness wear production. Prioritize budget for high-demand fitness apparel lines. Allocate resources for research and development in fitness wear.

Consider budget allocation for marketing and brand promotion. Allocate funds for quality control in fitness wear manufacturing. Invest in technology upgrades for production efficiency.

Plan budget for sourcing high-quality materials. Allocate budget for training and skill development.

·Supplier Research

Identify reliable suppliers for fitness wear materials. Evaluate suppliers based on quality, cost, and reliability. Consider suppliers with innovative material options. Assess supplier capacity to meet production demands. Evaluate supplier track record in the fitness wear industry.

·Goal Setting

Set clear objectives for fitness wear manufacturing. Define production goals based on market analysis. Establish quality benchmarks for fitness apparel. Set sales targets based on demand forecasting.

Outline sustainability goals for fitness wear production. Set goals for brand positioning and market penetration. Define customer satisfaction objectives. Establish innovation goals for fitness wear designs.

·Strategy Development

Develop a comprehensive strategy for fitness wear production. Align strategy with market analysis findings. Incorporate demand forecasting into production planning. Develop supplier engagement strategy for material procurement. Set strategic goals for market growth and brand positioning.

|

Factor |

Market Analysis |

Demand Forecasting |

Budget Allocation |

Supplier Research |

Goal Setting |

Strategy Development |

|

Objective |

Identify market trends |

Predict future demand |

Distribute financial resources |

Assess supplier capabilities |

Define business objectives |

Formulate action plan |

|

Key Activities |

Data gathering, SWOT analysis |

Historical data analysis, modeling |

Resource prioritization |

Vendor evaluation, background checks |

Setting KPIs, milestones |

Brainstorming, scenario planning |

|

Tools |

Market reports, analytics tools |

Statistical software, AI models |

Budgeting software |

Databases, audit reports |

Goal-setting frameworks |

Strategic planning tools |

|

Metrics |

Market share, customer preferences |

Sales projections, market growth |

ROI, cost-effectiveness |

Quality, reliability, ethics |

Timeline, achievability |

Feasibility, adaptability |

|

Challenges |

Data accuracy, competition analysis |

Predictive uncertainty, model accuracy |

Cost control, resource allocation |

Supplier reliability, compliance |

Clarity, realism |

Alignment with objectives |

|

Decision Making |

Product development, targeting |

Inventory management, production planning |

Funding allocations |

Partnership selection |

Prioritization, focus areas |

Tactical approaches, execution |

|

Impact on Negotiation |

Competitive advantage |

Supply-demand balance |

Cost management |

Quality assurance, risk mitigation |

Clarity in objectives |

Effective execution strategy |

Table on How To Prepare For Negotiation! Essential Steps!

What Are The Key Factors To Consider When Selecting A Fitness Wear Manufacturer?

·Production Capacity

Vital for fitness wear producers, capacity to meet demand is essential. Assessing their volume handling capability is key. Scalability to match market fluctuations is crucial. Output rate efficiency impacts delivery timelines. Larger orders should not strain quality maintenance.

High-capacity facilities must demonstrate consistency. Review past large-scale production effectiveness. Capacity assessments should include peak season handling. Align production abilities with brand growth projections.

·Quality Standards

Quality control is paramount in fitness wear production. Ensure adherence to stringent quality protocols. Use of durable, performance-based fabrics is a must. Consistent quality output is a non-negotiable factor. Transparent quality assurance processes are vital.

Regular quality audits ensure standard maintenance. Align manufacturer quality with brand values. International quality compliance is essential for global markets.

·Compliance Certifications

Certifications indicate adherence to standards and quality. Manufacturers must comply with global regulatory norms. ISO and other certifications reflect best practices. Ethical manufacturing and labor law compliance are critical. Environmental certifications denote sustainable practices.

Industry-specific certifications add credibility. Certifications can aid in brand positioning. Compliance ensures legal safety and reputation. Valid, up-to-date certifications are essential. Compliance goes beyond legal to ethical commitments.

·Innovation Capability

Innovation drives the fitness wear sector. Investment in research and development is key. Manufacturers should embrace new material technologies. Custom design and product innovation are important. Collaboration in innovation can lead to unique offerings.

A history of innovative product introductions is valuable. Innovation extends to manufacturing processes. Partnership with innovative manufacturers is beneficial.

·Sustainability Practices

Sustainable manufacturing is increasingly important. Commitment to eco-friendly practices and materials is crucial. Manufacturers should have sustainable supply chains.

Look for sustainability certifications. Global sustainability alignment is important. Practices should minimize environmental impact.

·Lead Times

Timely delivery aligns with market demands. Assess manufacturers' deadline adherence. Shorter lead times benefit market responsiveness. Align lead times with business cycles.

Contingency plans for delays are necessary. Efficient logistics and supply chain management are needed. Negotiate optimal lead times without incurring extra costs.

How To Navigate Minimum Order Quantities (MOQ)?

·Volume Flexibility

Fitness gear producers often adjust volumes in increments of 50 units. Seasonal demand influences order size, impacting fabric meters utilized. Larger orders often involve multiple design variations, testing resilience. Diverse size ranges require additional pattern adjustments, reflecting in volume tweaks.

·Price Scaling

Cost per unit varies inversely with quantity for fitness wear apparel. Fabric types, e.g., Lycra or polyester, influence base price. Additional features like moisture-wicking add to the cost.

Bulk orders may attract discounts, impacting final unit pricing. Specialized stitching techniques can further adjust pricing.

·Inventory Planning

Forecasting demand is crucial for effective inventory control. Fitness wear makers often set quarterly inventory reviews. Anticipating seasonal trends affects stock levels.

Sudden market shifts necessitate flexible stock adjustments. Efficient warehousing strategies minimize overstocking risks. Technology integration aids in precise inventory forecasting.

·Sample Testing

Prototyping is vital before mass production. Fitness wear trials assess fabric stretchability and comfort. Durability tests under simulated wear conditions are common.

Feedback on prototype fit leads to design refinements. Colorfastness checks ensure enduring vibrancy. Final approval hinges on sample performance under stress tests.

·Long-Term Commitment

Enduring partnerships with manufacturers yield mutual benefits. Committing to annual contracts can secure better rates. Regular reevaluation of terms fosters ongoing collaboration.

Long-term deals often include performance-based incentives. Maintaining consistent quality standards cements such relationships. Regular business reviews assess partnership efficacy.

·MOQ Negotiation

Initial negotiations often start around 300 pieces per style. Flexibility in MOQ depends on production process capacity. Custom designs may influence minimum batch sizes.

Seasonal factors play a role in MOQ flexibility. Establishing early rapport can lead to advantageous MOQ terms. Strategic planning helps in aligning MOQ with demand forecasts.

|

Criteria |

Description |

Impact on Cost |

Risk Level |

Suitability |

Flexibility |

Timeframe Impact |

Ideal For |

|

Volume Flexibility |

Adapts to order size |

Variable |

Medium |

All sizes |

High |

Adjustable |

New brands |

|

Price Scaling |

Varied cost per unit |

Decreases with volume |

High |

Bulk orders |

Moderate |

Fixed tiers |

Large orders |

|

Inventory Planning |

Stock level management |

Reduces excess |

Low |

All sizes |

High |

Strategic |

Seasonal demand |

|

Sample Testing |

Quality assessment |

Initial investment |

Medium |

New products |

Low |

Pre-production |

Quality check |

|

Long-Term Commitment |

Ongoing partnership |

Stable over time |

Low |

Established brands |

High |

Long-term |

Strategic growth |

|

MOQ Negotiation |

Order size terms |

Negotiable |

Medium |

All sizes |

High |

Negotiable |

Custom orders |

Table on How To Navigate Minimum Order Quantities (MOQ)!

Negotiating Terms And Conditions!

·Payment Terms

Negotiating favorable terms balances cash flow. Standard terms often involve 30-day payment cycles. Advance deposits may be required for large orders.

Flexible payment schedules can be negotiated based on order size. Late payment penalties are typically outlined in contracts. Incentives for early payments can be beneficial.

·Delivery Schedules

Timely delivery is critical in the fitness wear industry. Production lead times vary based on design complexity. Seasonal peaks may impact delivery timelines.

Rush orders often incur additional charges. Regular updates on production progress aid planning. Contingency plans for delivery delays are essential.

·Quality Assurance

Maintaining high standards is paramount for fitness gear. Regular quality checks are conducted during production. Material sourcing impacts overall quality. Defect rates are closely monitored and addressed. Compliance with industry standards is non-negotiable. Continuous quality improvement is a shared objective.

·Order Amendments

Flexibility in order changes accommodates market shifts. Deadlines for making changes are typically set early. Costs associated with amendments vary. Frequent changes may affect delivery times. Clear communication on changes prevents production hiccups. Balancing flexibility with production efficiency is key.

·Confidentiality Clauses

Secrecy is crucial for proprietary designs. Non-disclosure agreements protect intellectual property. Confidentiality extends to materials and manufacturing processes.

Breach of confidentiality can lead to legal consequences. Regular audits ensure compliance with confidentiality terms. Trust is fundamental in maintaining confidentiality.

·Dispute Resolution

Effective mechanisms are necessary for resolving conflicts. Mediation often precedes legal action. Clear contract terms help in dispute avoidance.

Regular communication can prevent misunderstandings. Binding arbitration clauses may be included in contracts. Swift resolution of disputes maintains business continuity.

Conclusion

Negotiations with Fitness Wear Manufacturers, successful outcomes hinge on detailed knowledge of garment specs and production processes. Embracing a strategy encompassing component understanding, from yarn types to seam techniques, leads to favorable terms.

Final agreements reflect a blend of quality, cost, and functionality. For enduring partnerships in fitness apparel, visit SANSANSPORTS where expertise meets innovation in every stitch.

Inquire(

Inquire(

HOME

HOME Private Label vs. Custom Design: What's Best for Your Fitness Brand?

Private Label vs. Custom Design: What's Best for Your Fitness Brand?  You May Also Like

You May Also Like

Tel

Tel

WhatsApp

WhatsApp

Email

Email

Address

Address