The Material Trend for Outdoor Waterproof Fabric

2023-09-18

2023-09-18

Sansansun

Sansansun

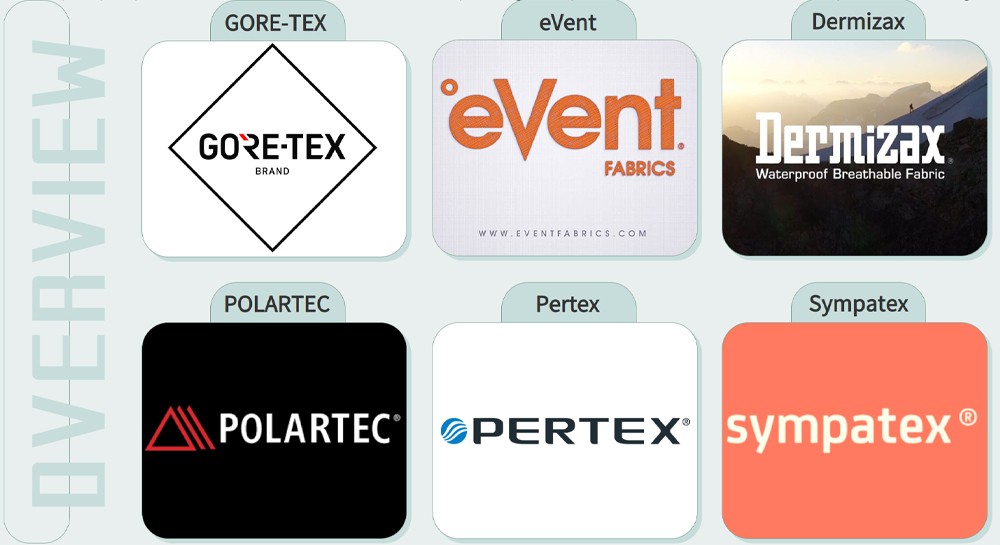

Overview

With the rise of outdoor activities, the demand for outdoor clothing has gradually increased. The functionality of clothing has received attention, especially the basic waterproof function has become one of the important factors that people consider when choosing outdoor equipment. In addition to waterproof function, waterproof fabrics usually have breathability and abrasion resistance. This report, sponsored by Athletic Wear Suppliers, focuses on globally renowned brands of waterproof fabrics/membranes such as GORE-TEX, eVent, Dermizax, POLARTEC, Pertex, and Sympatex, introducing their brand history, waterproof function principles, product line information, and commercial cases, providing development ideas and materials for outdoor sports series clothing.

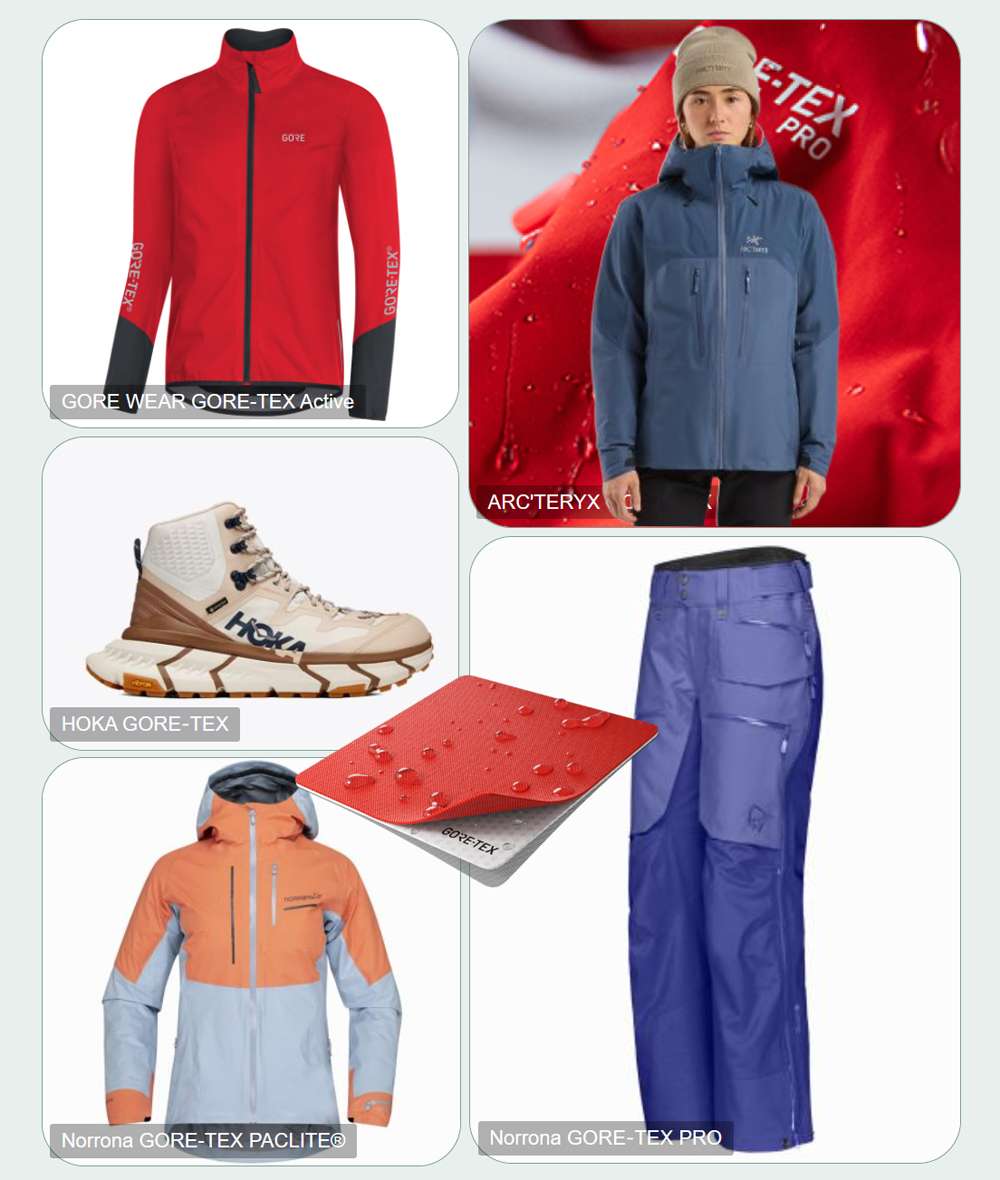

GORE-TEX

Brand Introduction: In the 1970s, the American company Gore introduced the waterproof, windproof, and breathable fabric GORE-TEX, which is known as the "fabric of the century".

Working Principle: Each square inch of GORE-TEX membrane is made up of 9 billion pores. Each pore is 20,000 times smaller than a water droplet, so rain cannot enter, but 700 times larger than a water vapor molecule, allowing sweat to pass through these pores, achieving both waterproof and breathable effects.

Applications: Used in outdoor scenes such as skiing clothes, mountaineering clothes, windbreakers, jackets, pants, boots, gloves, etc.

Business Collaboration Brands: GORE WEAR, ARC'TERYX, Norrona, HOKA, ecco, SITKA, etc.

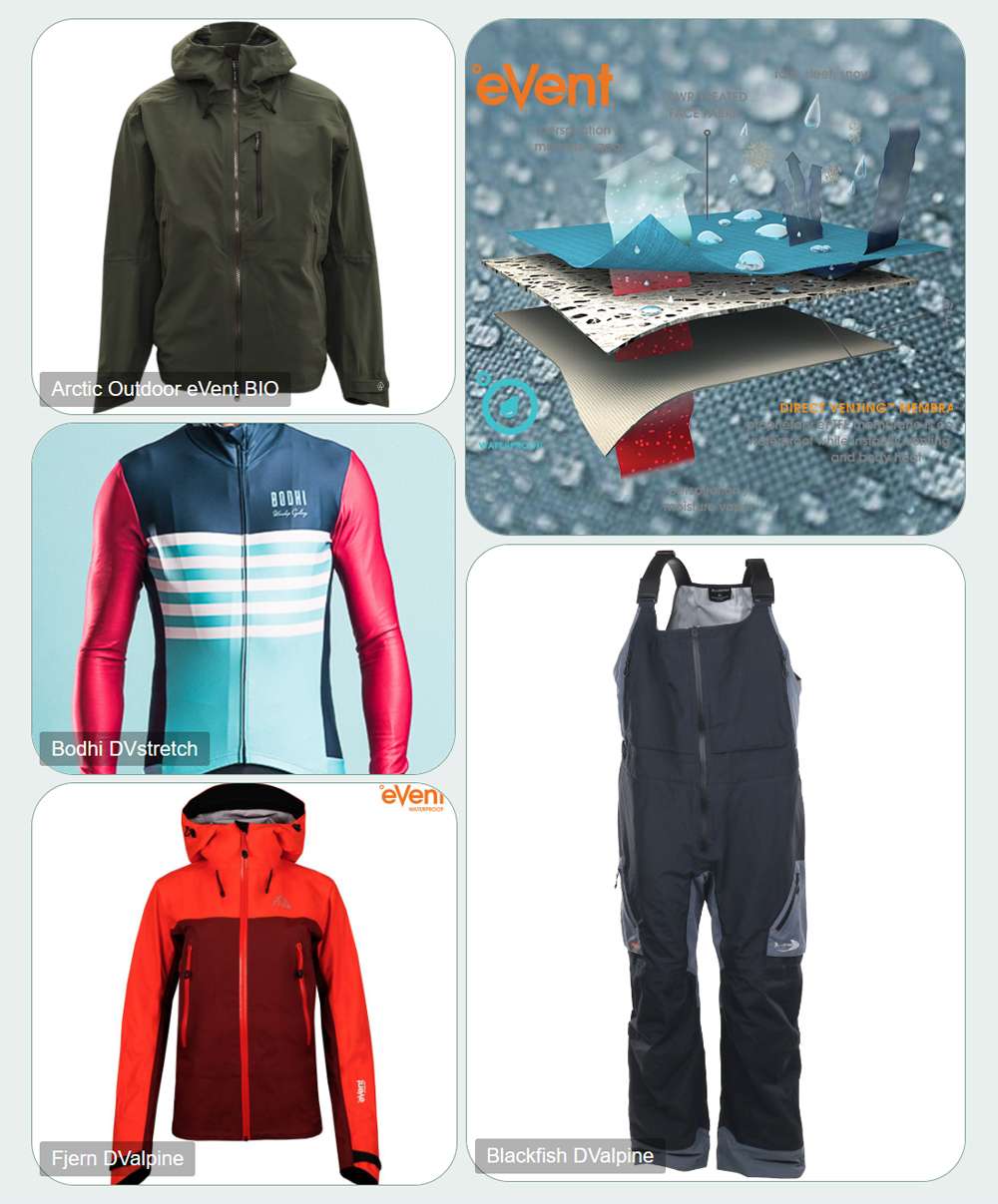

eVent

Brand introduction: Developed by GE General Electric in 1999, waterproof fabric.

Working principle: The exclusive Direct Venting technology includes billions of micro-pores in the thin film, which has natural hydrophobicity. It allows eVent fabric to be 100% waterproof and 100% breathable. When worn, the micro-pores can immediately release water vapor accumulated inside clothing and shoes, keeping the body dry and comfortable under a wide range of temperature and humidity conditions.

Fabric application: Used in outdoor scenarios such as skiing wear, mountaineering wear, cycling wear, jackets, pants, shoes, sleeping bags, and gloves.

Commercial collaboration brands: Fjern, BIGPACK, Arctic Outdoor, New Balance, Urban Research, Vifra, etc.

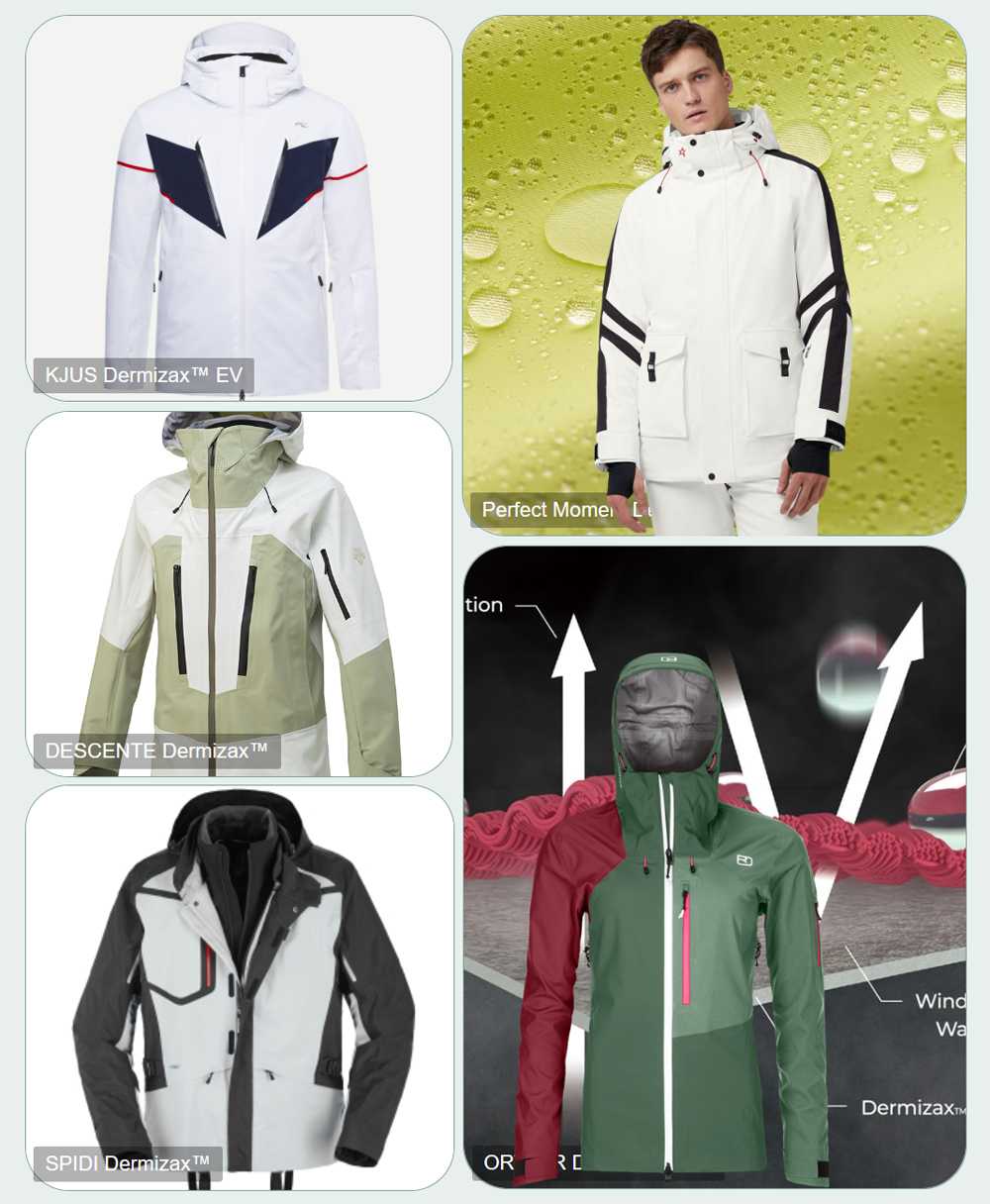

Dermizax

Brand Introduction: In 1995, Toray of Japan launched the waterproof and breathable PU hydrophilic composite film material Dermizax™.

Working Principle: Dermizax™ is a fabric with highly complex and technical membrane that achieves the highest level of waterproofness, breathability, and condensation resistance. With a waterproof rating of 20,000 millimeters, it allows moisture to escape while retaining heat, keeping the wearer's body temperature at a comfortable level, and has good elasticity.

Applications: Used in outdoor settings such as skiwear, mountaineering clothing, motorcycle gear, golf jackets, and pants.

Commercial Partner Brands: KJUS, Perfect Moment, SPIDI, DESCENTE, etc.

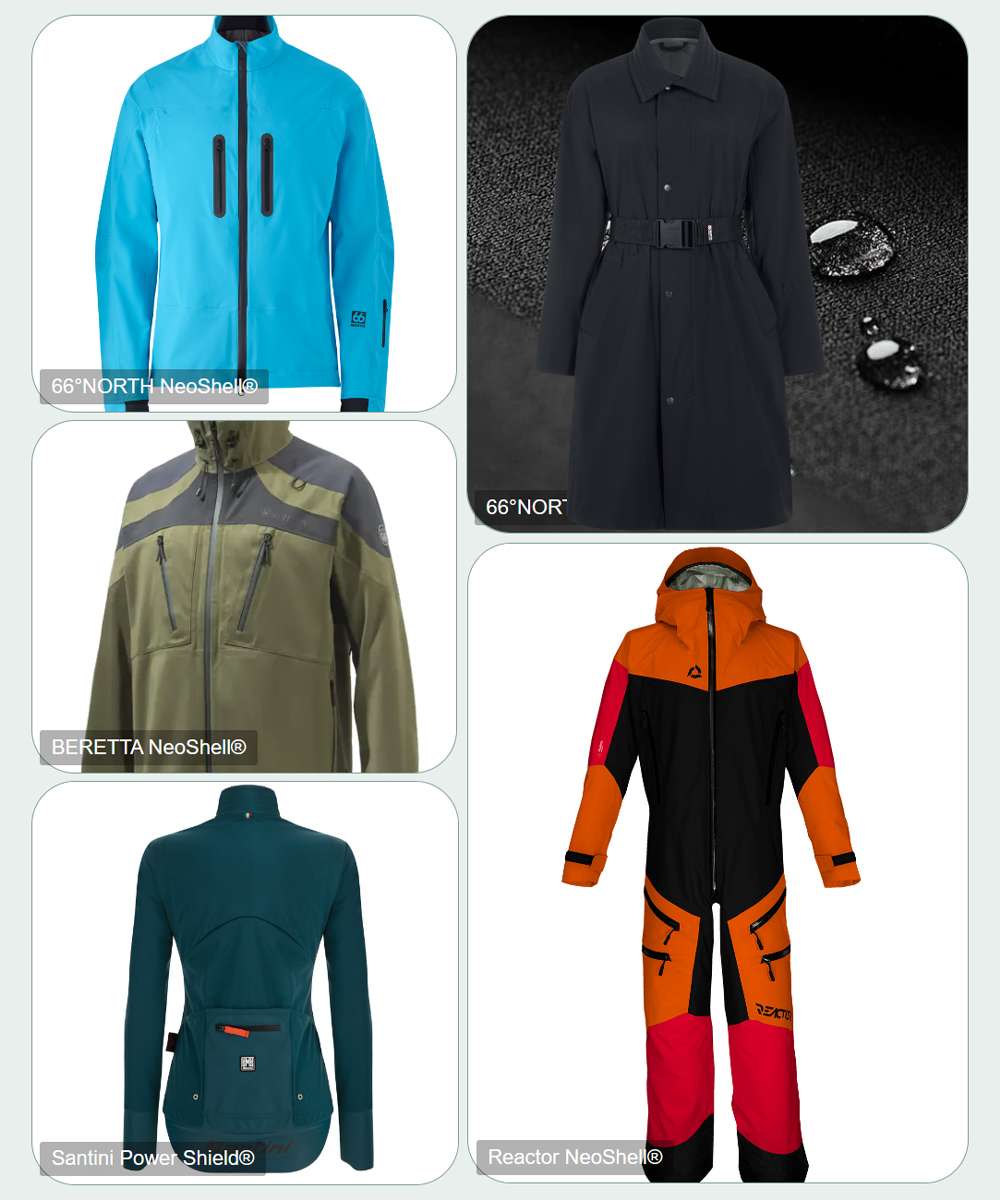

POLARTEC

Brand Introduction: The waterproof and breathable fabric released by POLARTEC in 2011 excels in fleece fabric.

Working principle:

1. NeoShell® achieves higher breathability through the submicron membrane structure in the fabric core. It releases heat and sweat without generating high pressure, and continuous air exchange enhances natural temperature regulation, free from external influences.

2. Power Shield® is made of 48% non-GMO plant-based biomaterials. Based on bio-based, PFAS-free, adventure-grade waterproof and breathable fabric technology, it is more breathable, waterproof, and sustainable.

Fabric application: Used in outdoor scenarios such as skiwear, mountaineering clothing, cycling clothing, jackets, and pants, as well as daily outerwear like windbreakers and down jackets.

Commercial collaboration brands: 66°NORTH, Reactor, Santini, NOBULL, BERETTA, Fox Racing, etc.

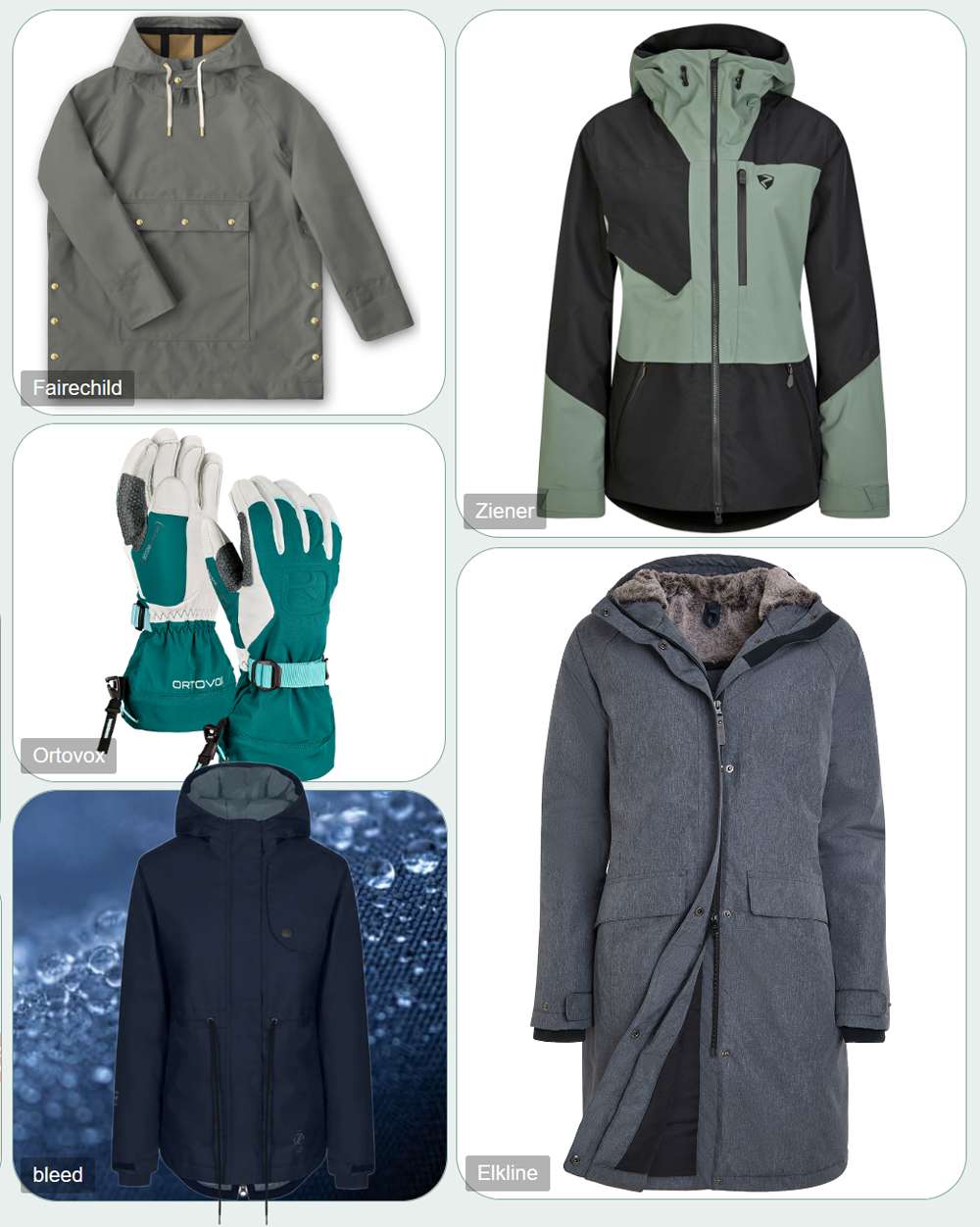

Pertex

Brand introduction: Developed in 1979 by British material merchant Perseverance Mills.

Working principle: Pertex is composed of versatile 2, 2.5, and 3-layer structures, combining lightweight outer fabrics with waterproof, windproof, and breathable membranes. The durable water repellent (DWR) finish applied to the outer fabric prevents rain and snow, helping to maintain breathability, and it is extremely lightweight and abrasion-resistant.

Fabric application: Used in outdoor scenarios such as skiing clothing, mountaineering clothing, cycling clothing, jackets, pants, shoes, sleeping bags, and gloves.

Commercial cooperation brands: Macpac, SALOMON, Goldwin, ORTOVOX, Kathmandu, etc.

Sympatex

Brand Introduction: Sympatex was founded in Germany in 1986 and is focused on the development and production of high-performance functional fabrics and membranes.

Working principle: Instead of using microporous technology, Sympatex utilizes a physical structural principle that can withstand static water pressure of over 40000+ millimeters. The hydrophilic molecular chains in the membrane absorb water vapor and release it to the outside. The membrane can also bond with polyester surface layers and inner fabrics to form a composite.

Application: Sympatex fabrics are used in outdoor scenarios such as skiwear, mountaineering clothing, cycling apparel, windbreakers, pants, shoes, raincoats, tents, hats, and gloves.

Business Cooperation: Ortovox, Ziener, Lurchi, Rotauf, Lagoped, Elkline, etc.

Summary

Waterproof fabrics/membranes are mainly used in outdoor sports categories such as hiking jackets and ski suits, as well as accessories such as footwear and gloves. They are also becoming popular in lightweight outerwear categories such as casual windbreakers and jackets.

Brands have successively iterated on the waterproof performance, launching waterproof functional fabrics/membranes that cater to different scene demands, while also focusing on improving breathability, lightness, and wear resistance. At the same time, with the influence of low-carbon sustainability, various enterprises have increased their investment in environmentally friendly bio-based/regenerated material waterproof membranes, starting to introduce mature bio-based/regenerated material membranes and gradually achieving 100% renewable/degradable.

Inquire(

Inquire(

HOME

HOME Active Commuting -- The Design Development of Athleisure Style

Active Commuting -- The Design Development of Athleisure Style  You May Also Like

You May Also Like

Tel

Tel

WhatsApp

WhatsApp

Email

Email

Address

Address